●Product Usage

With the rapid development of the electroplating industry, the requirements of the electroplating automatic production line control system have increased. The system can realize the intelligent centralized control of the power supply, which can effectively improve the communication speed and control accuracy. Compared with traditional power analog networking, it has the advantages of more stable operation, higher accuracy, long transmission distance, low networking cost, and convenient debugging. It is widely used in metal plastic electroplating production lines, continuous electroplating production lines, zinc-nickel alloy electroplating production lines, and high-quality power intelligent control of various barrel plating production lines, as well as automatic brightener addition occasions.

●Product Features

High control accuracy: using digital transmission technology, the communication distance is 1200m without attenuation, and the digital control accuracy reaches 1%;

Low networking cost: using digital networking technology, equipped with RS-485 communication interface, a double glue line can be connected to all power equipment, can be directly connected with PLC or industrial computer, reducing a large number of analog output modules, switch modules , Power transmitter and cable;

Debugging is more convenient: adopt the international general MODBUS protocol, only need to set the communication address of each power supply, no need to debug on site, reduce labor cost;

The communication is faster: the maximum communication rate is 38400bps, and it can accommodate 128 rectifiers into the network at the same time;

More reliable operation: The control system uses a 32-bit single-chip microcomputer as the core, which realizes the conversion of the communication protocol between PLC and power supply, and completely solves the problem of protocol mismatch between PLC and power supply. Due to the direct reading and writing of PLC memory, the developer You can focus on the development of the production line and only need to set the relevant parameters in the corresponding memory unit of the PLC, which greatly reduces the research and development pressure.

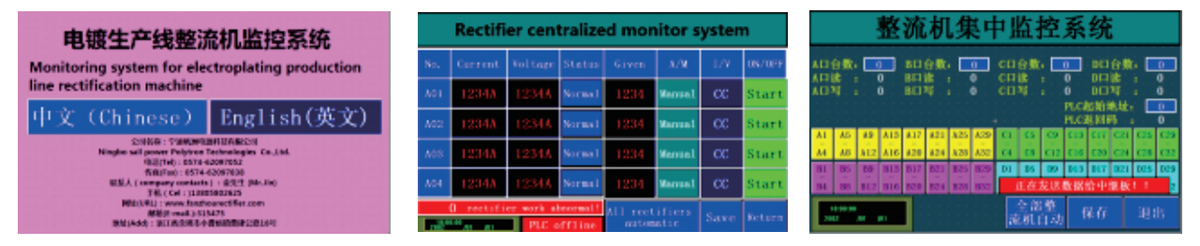

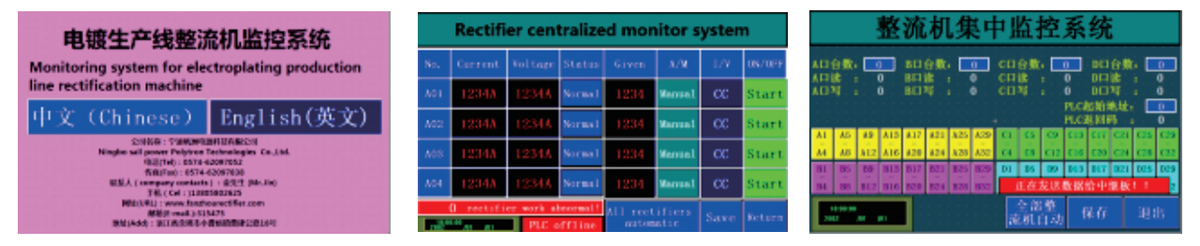

●Human machine diagram

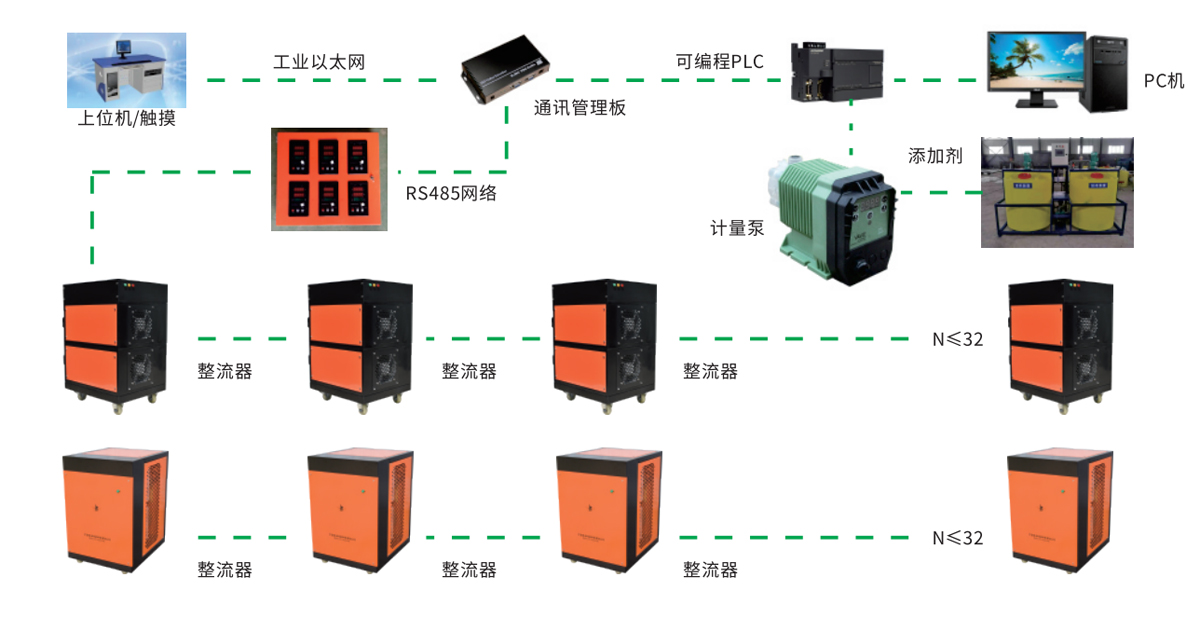

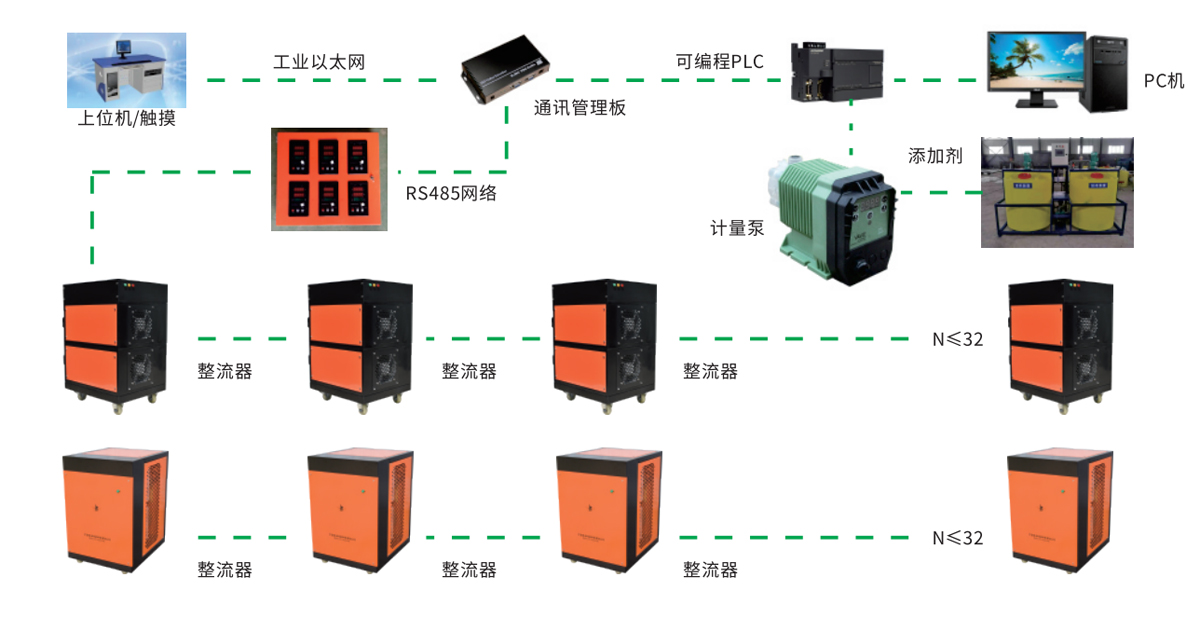

●RS485 remote network control system diagram